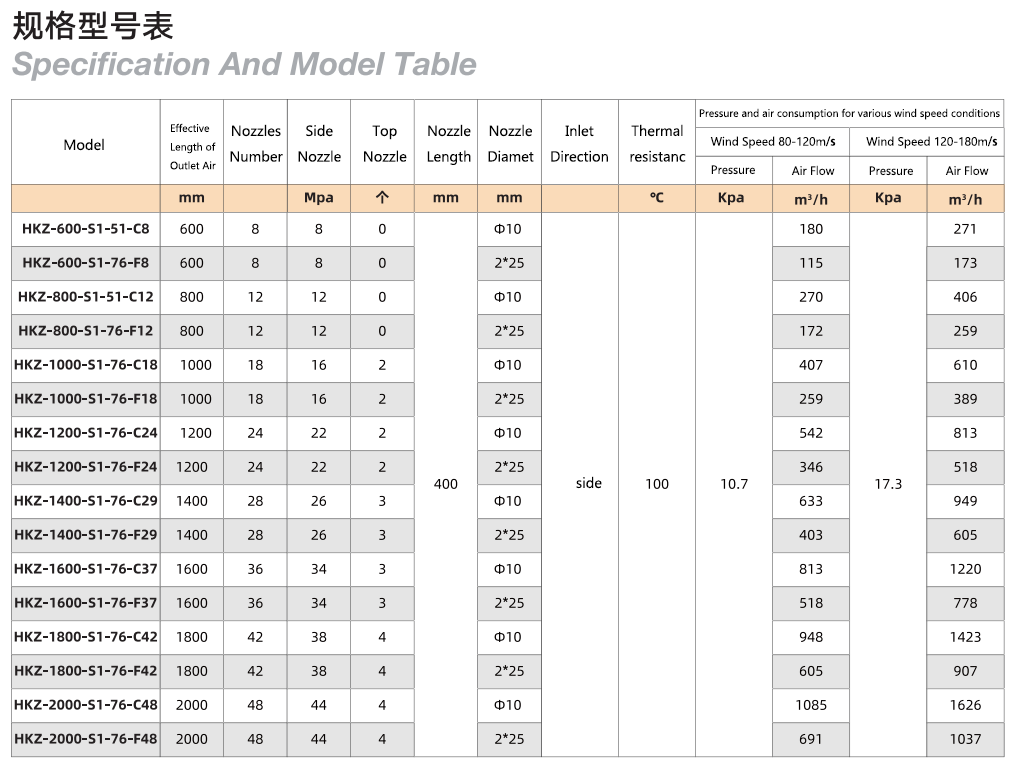

DEREIKE Air Knife HKZ-1000-S1-76-F18

DEREIKE Air Knife HKZ-1000-S1-76-F18

General characteristics:

●Maximum air flow up to 2480 m3/h;

●Rated vacuum up to -730 mbar;

●Nominal pressure up to 1040 mbar;

●High efficiency IE2/IE3 available;

●With thermal protection (PTC);

●100% oil free, easy installation, maintenance free;

●Certification CE, ROHS, UL, ATEX;

●Broadband frequency and voltage used worldwide;

●High quality bearing used for high temperature protection up to 180℃-200℃;